Engineering plastics

Compounds are enhanced by adding glass fibers, minerals, or other materials to thermoplastic polymers, which are chosen based on their properties in the manufacturing of engineering components.

These materials offer good mechanical properties, good chemical resistance, low abrasion and deterioration. Due to low density and easy processing they substitute traditional materials including metal.

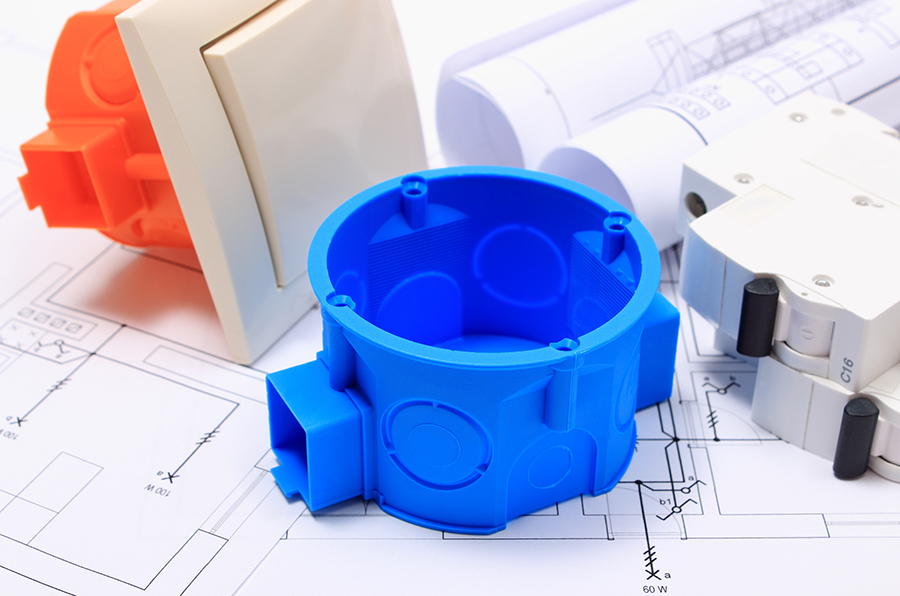

Wide range of application they found for processing components for automotive, electrical, electronics industry as well as in building industry and many other areas.

PP Compounds

Polypropylene Compounds

Polypropylene Compounds

Properties:

Polypropylene – Homopolymers and Copolymers, reinforced with minerals, EPDM, glass fibres and glass beads.

New in our portfolio are PP LGF compounds, produced through a specialized engineering process and containing long fibres up to 50%. These products meet high mechanical requirements, even at elevated temperatures and serve as alternatives to light metals, thermostats, and costly engineering plastics.

We also offer materials modified with additives, they can be adjusted to customer requirements.

Specification:

Filled with:

– Mineral up to 40%

– Glass fibres up to 50 %

– EPDM up to 30 %

UV and thermoresistant, good flame resistance

High tensile strength and stiffness

Alkali-resistance

Fields of application:

Automotive and electrical industry, white goods, building industry

TPE Compounds

Thermoplastic elastomer compounds

Properties:

Thermoplastic elastomer TPE-S (based on Styrene-block-Copolymers), TPE-V (based on EPDM / PP), TPE-E (based on Polyurethane).

We offer wide range of radiation-crosslinkable TPE compounds for PS, ABS, ABS-blends, SAN, ASA, PC, PA, PA-blends, POM, PMMA and PPO with/in different hardness.

For the highest thermal resistance radiation-crosslinkable TPEs are offered.

Other properties are: good compression set, acoustic insulation, oil resistance, self-extinguishing according to UL94.

Specification:

Shore hardness of 21 Shore 00 (Jelly-compounds) until 75 Shore D

Good waterproof properties

High stiffness/strength

Good scratch resistance

Oil resistance

High dimensional stability

Dry surface feel

Radiation-crosslinkable

Fields of application:

Injection moulding, multi component moulding and extrusion

TPE is used for automotive, electrical, consumer products, medical applications, tool manufacturing, sporting goods and leisure wear.

PBT Compounds

Polybutylenterephthalate Compounds

Polybutylenterephthalate Compounds

Properties:

We offer a wide range of compounds including unreinforced, glass fiber reinforced, impact strength modified, and flame-protected variants. These compounds are known for their high hardness, stiffness, and resistance to wear. They exhibit excellent sliding and abrasion resistance, as well as high toughness even at minus degrees.

Specification:

Density: 1,31 – 1,66 g/cm³ (ISO1133)

Impact strength Charpy: 4 – 11 kJ/m² (ISO179 1eA / 23°C)

Tension / elastic modulus: 2.600 – 11.000 MPa (ISO 527-1)

Fields of application:

Polybutylene terephthalate (PBT) is utilized in electrotechnology for casing applications and in vehicle construction for plug connections. It is also commonly found in household items such as shower heads and irons. Processed in fibers you will find them in toothbrushes or as a coating of fibre optic cables.

PA Compounds

Polyamide Compounds

Polyamide Compounds

Properties:

It concerns engineering plastics, which are filled with varying content of glass fibres as well as mineral fillers as Talcum.

Beside the standard products we also offer types according to customer specifications as well as radiation-crosslinkable Polyamide-materials based on PA 6, PA6.6, PA 11 and PA 12.

Specification:

Glass fibre content up to 50%

Impact strength Charpy: 5 – 12 kJ/m² (ISO 179 leA 23°C)

Tension elastic modulus: 2.800 – 9.700 MPa (ISO 527-1)

Fields of application:

These products are used especially in automotive- and electrical industry, engineering as well as building industry, due to the excellent properties.

PC Compounds

Polycarbonate Compounds

Polycarbonate Compounds

Properties:

We offer PC compounds that can be pigmented and modified according to customer specifications already from smallest quantities of 25 kg on.

These products are made of virgin compound with little addition of premium recycled materials, deriving from production waste.

The outcome of this is an economic alternative to new goods.

Specification:

VDE –glowing wire test by 850°C till 960°C and 1.0 as well as 2.0 mm Material thickness (DIN EN 60695-2-12)

UL 94 HB, V-2, V-1, V-0 (File E 178422)

Fields of application:

Mechanical components for electric industry.

ABS Compounds

Acrylonitrilebutadiene-Styrene Compounds

Properties:

ABS compounds can be offered glass reinforced, high impact,

flame resistant and also pigmented according to customers requirement

Fields of application:

High surface hardness

Good impact strength

Good oil resistance

Elongation at break: 15 – 30% (DIN 53455)

E-modulus: 1.900 – 2.700 MPa (DIN 53457

Fields of application:

Automotive, electrical, furniture industry as well as consumer goods with higher demand on impact strength.