Fiberglass

E- / ECR-Glass

E-Glass (E = electric): is considered to be the standard glass fiber

ECR-Glass (E-Glass corrosion resistant): fiber of very high corrosion resistance, free of boron and fluorine

Glass fibers are produced from the melt of a specific glass type (for example E-Glass). They consist of a uniform filament diameter and appear as continuous fiber or as staple fiber with certain length, using different sizings. Engineering plastics are aging, weather and chemically resistant and non-combustible, have a high elasticity modulus, which is improving the mechanical properties.

Engineering plastics are among the most important materials in the field of engineering, boasting a wide range of applications. They are extensively used in industries such as aerospace, boat building, automotive, white goods, electrical, and the sport and leisure sectors.

Chopped strands

For thermoplastics, thermosetting and high-performance plastics

For thermoplastics, thermosetting and high-performance plastics

ECTA offers a wide range of high quality chopped strands, manufactured in in-line and off-line production process.

Thermoplast:

PA, PP, PET, PBT, PC, POM, ABS, PVC

High-performance plastics (PPA, PEEK, PTFE, PPS, LCP)

Thermosets:

BMC

Properties:

Excellent flowability and strand integrity

Very good compatibility with polymer matrix

Specification:

Filament Diameter: 6 – 13 µ

Chopped length: 1,5 – 12 mm

Fields of application:

Automotive, Electrical, Construction industry, White goods

Direct roving

Roving for weaving, winding, pultrusion, LFT applications

Roving for weaving, winding, pultrusion, LFT applications

Application: Weaving, Filament winding, Pultrusion, LFT(Long Fiber Thermoplastic)

Properties: Low fuzz processing and excellent impregnation capabilities, compatible with unsaturated polyester, epoxy, and vinyl ester resins.

Specification: 300 – 9.600 tex Filament Diameter: 13- 24 µ

Fields of application: Automotive, Electrical, Construction industry, White goods

CONVENTIONAL ROVING

SMC (Sheet molding compound)-Roving

SMC (Sheet molding compound)-Roving

Properties: Superior choppability and optimal strand integrity, providing good mechanical properties and an excellent Class A surface finish. Compatible with unsaturated polyester resins.

Specification: 2.400 – 4.800 tex Filament diameter: 14- 16 µ

Fields of application: Automotive and Electrical industry, Sporting goods

Spray up roving

Application: Spray up process, centrifugation process

Properties: Superior choppability and dispersion of monofilaments Compatible with unsaturated polyester and vinyl ester resins

Specification: 2.400 – 4.800 tex Filament diameter: 13- 24 µ

Fields of application: Automotive industry, bathtub manufacturing

Chopped strand mats

Powder bonded,

Powder bonded,Emulsion bonded

Application:

Hand lay-up, continuous plate making

Properties:

Compatible with unsaturated polyester and vinyl ester resin

Specification:

Unit weight: 100 – 900 g/m²

Width: 250 – 3.000 mm

Standard weight: 1.270 mm

Application fields:

Boat building and vehicle construction

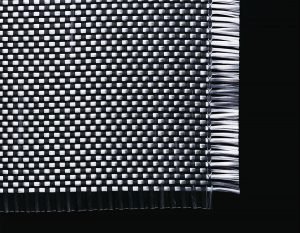

Woven Roving

Applications:

Applications:Hand lay-up

Properties:

Compatible with unsaturated polyester and vinyl ester resin

Specification:

Linen weave in 0° / 90° orientated non-weaved

Unit weight: 300 – 1.000 g/m²

Roll width: 250 – 3.350 mm

Standard width: 1.270 mm

Fields of application:

Shipbuilding and automotive industries

Milled glass fiber

Milled glass fiber – not just a filler

Properties:

Milled fiber helps reduce shrinkage and increases flame retardance, enhancing the dispersion and flowability of plastic granules. Unlike standard milled fillers, milled fiber maintains consistent quality in grit size and color. We offer milled fiber with or without a silane-based surface treatment.

Milled fiber is reproducible in the same quality in terms of grit size and color, distinguishing it from standard “milled filler.”

Specification:

Fiber length: 75-200 µ

Density: 0,2-1 g/cm³

Colour: white

Fields of application:

Compounds, Paints and coatings, gelcoats

Special products

- Flat fiber

- Multi-axial fabrics

- PP core mat

- Surface mat

- Combo mat

Detailed consultation regarding special products on request.